1. Aluminum sheets and aluminum alloy strip with hot-rolled state, annealed state, various levels of soft state and a variety of heat treatment state supply.

2. Aluminum sheets in the hot before the preparation, including the ingot quality inspection, soaking, sawing, milling, aluminum and heating.

3. Semi-continuous casting when the cooling rate is very high, the diffusion process in the solid phase is difficult, the ingot is easy to form internal chemical composition and uneven organization, such as intraocular segregation, so that plastic.

4. The surface of the ingot segregation problems, slag, scarring and cracks and other defects should be milling (see non-ferrous metal alloy ingot milling surface), which is to ensure good quality of the finished product is an important factor.

5. Hot-rolled: aluminum alloy ingot hot rolling is to provide cold for rolling, or the direct production of hot-rolled plate.

6. Hot rolling process system, including pass down rate, rolling temperature, rolling speed and lubrication cooling.

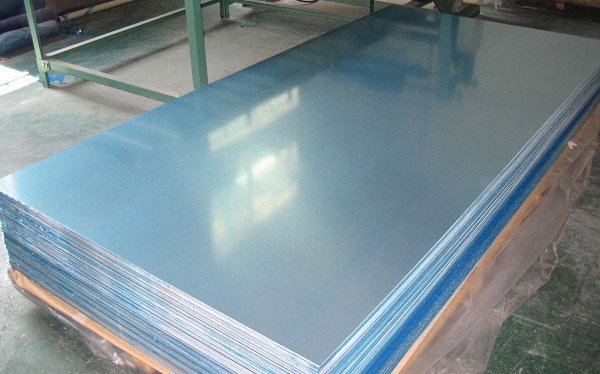

Aluminum Sheets